Supply Chain Optimization (SCO)

Continuously Optimize your Inventory to meet Performance Goals with Precision and Low CostIs your Spares Inventory

still Optimal?

Is the performance of your optimized spares solution beginning to deteriorate?

Are the assumptions and parameters used in your spares provisioning still valid?

Are you confident that your repair priorities are optimized for operational availability and cost?

Are you sure that your re-supply trigger points and minimum demand quantities are still appropriate?

For many years, supply chain managers have been discovering the benefits of spares optimization techniques, often getting twice the performance out of the same investment. Many have also noticed that these improved solutions are less stable than sub-optimal solutions, with initial performance soon dropping off and sometimes becoming indistinguishable from sub-optimal methods.

Normally, asset managers operate within their organization’s inventory control policies (such as trigger points and minimum demand quantities) based on a range of analytical methods from single item modelling to sophisticated spares optimization. No matter how it is done, inevitable changes and fluctuations in underlying assumptions, conditions and attributes can result in this fixed guidance becoming outdated just as quickly as the spares solution it’s based on.

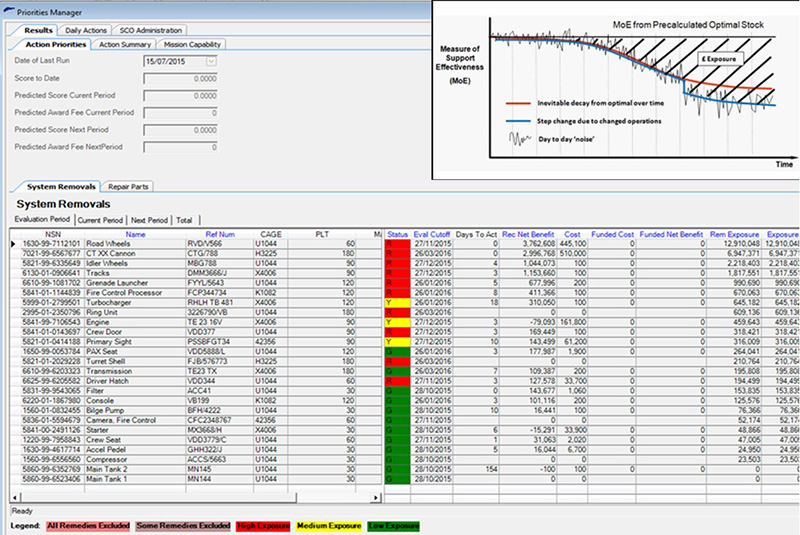

TFD’s Support Chain Optimization (SCO) bolt-on software solution for conventional inventory management systems solves this problem. SCO delivers continuous optimization, allowing managers to meet near-term, periodic performance goals with precision and at the lowest possible cost. Our scalable approach uses rich short-to-medium term simulation modelling, rather than long-term steady-state analytical methods that enable agile supply chain response through the adoption of reactive and dynamic inventory policy.

SCO provides near real-time intervention advice to restore and sustain optimum system performance by enabling you to: identify the parts in a support package which will run out in sufficient time to take effective action; identify the remedial actions that will prevent future support system default; prioritize the remedial actions by cost and the lead time needed to take action; justify the business cost benefits of early action; and predict future support package performance.

SCO

Provides automated advice to asset managers with timely, pointed and optimized decision guidance

Delivers continuous availability-based inventory optimization that sustains lower cost mission capability

TFD’s SCO provides a quantum step change in inventory management and offers very significant cost avoidance of 25-33%

Support Chain Optimization (SCO) – Continuously Optimize your Inventory to Meet Performance Goals with Precision and Low Cost

Further information about TFD tools, techniques, and methodology can be found on our downloads page.