EDCAS

The Defacto Standard for Cost and Level of Repair AnalysisAre You Designing to Cost?

Have you costed the best design for your new equipment?

Have you defined the best level of repair strategy for your support solution?

Have you evaluated the impact on supportability and cost of part and configuration design trade-off?

Have you understood the logistics performance of design alternatives?

As in-service lives are extended, obsolescence grows and technology insertion becomes prevalent, we often experience Life-Cycle Costs (LCC) that extend beyond initial expectations. With increasing pressures on equipment procurement and support budgets, it is paramount that opportunities for improving the cost and performance of systems and their support are identified; not only during the design and development phases, but also throughout the system’s life-cycle. EDCAS (Equipment Designers Cost Analysis System) is the ideal tool to help you seize these opportunities.

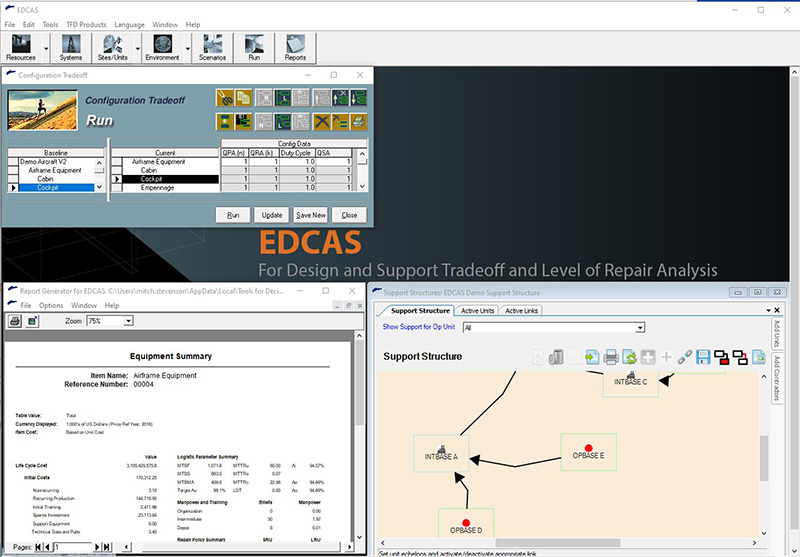

EDCAS is the decision support tool of choice for systems engineers, logistic planners and cost analysts seeking to identify cost‑effective design and support strategies throughout the design, development and in-service phases of a system’s life-cycle. By including the impact of Level of Repair in its LCC calculations, EDCAS will identify the lowest cost support policies for all system assemblies and, with its complete trade-off analysis capability, EDCAS users can evaluate the LCC impact of system design choices. EDCAS will also help you understand and assess cost risk through sensitivity analysis.

With over 1000 government and industry users worldwide, EDCAS is recognized as the Defacto Standard for Design Choice, Cost Assessment and Level of Repair Analysis. EDCAS brings logistic concerns inside the systems engineering decision loop and provides a rapid, intuitive tool to answer the design and supportability questions necessary to establish the required levels of system availability within an affordable budget.

EDCAS

Evaluate the Life-Cycle Cost (LCC) of an equipment design choice

Compare the LCC of alternative system designs

Identify the lowest cost repair policies for all assemblies in a system (LORA)

Perform trade-off analysis for part attributes and alternative configurations

Carry out sensitivity analysis on any combination of data inputs

The Defacto Standard for Cost and Level of Repair Analysis

Further information about TFD tools, techniques, and methodology can be found on our downloads page.